- Every project owned and lead to industrialisation;

- Development from concept;

- Design for Manufacture (DFM), Design for Assembly (DFA);

- Tolerance stack analysis;

- FMEA;

- Medical product design;

- 3D modelling with Creo Parametric;

- Design of jigs, fixtures and metrology gauges;

- Follow already created/developed concept;

- Project management;

- Tool qualification process involvement;

- Specification creation for specific industrialisation tasks;

- Documentation control;

- PLM workflow creation adjusted to current processes;

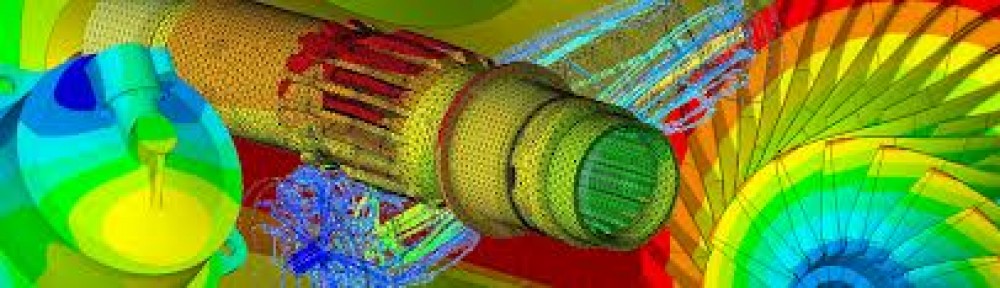

- Structural analysis FEA (Creo Simulate);

- Chemical compatibility;

- Materials selection;

- Aging factors consideration;

- Two patents in first two years;

- Design of magnetic drive system that increased torque transfer efficiency by

magnitude of 4 in comparison to previous versions and decreased complexity; - Seven concurrently run projects (upstream and downstream technologies: –

filtration, fermentation, bacteria cultures, conjugate drug delivery); - Structural analysis of fluid handling devices – FEA (Take One 2”, Chromatography,

Bioreactors); - Flow analysis of fluid handling devices – CFD (Chromatography);

- Influence in internal standards, workflows and PLM adjustment allow leaner design

process; - Innovative conceptual design to reduce assembly and avoid additional process –

purely mechanical joining method; - Magnet levitating impeller design issues resolving;

Tools:

- Creo Parametric

- SAP PLM

- 3D Printing (Objet, Formlabs, Ultimaker)